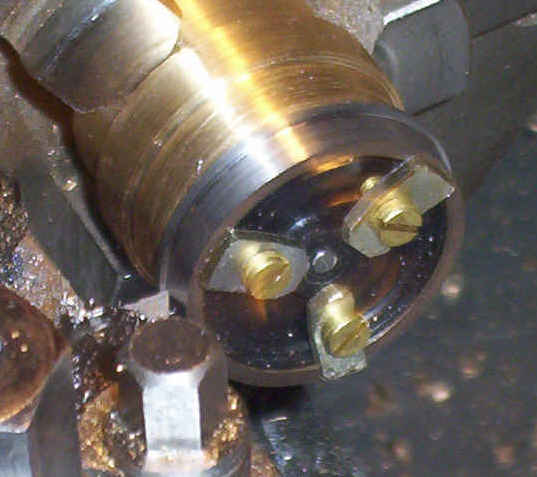

| To machine a set of wheels, it is merely a matter of

following the same process for each wheel. Set the compound slide to an

angle of 3 degrees, to match the prototype's 1 in 20 coning. Mount a wheel

on the mandrel, and clamp as per the photo. I was reducing the diameter by

about .056", but don't have indexable dials. I therefore played around

moving the saddle and cross slide until I reached the point where the tool

would cut the tyre and reach the flange at the desired diameter with the

cross slide dial on zero. This wasn't essential, but it helped. Once you

have done this, don't move the saddle - lock it to the bed if you wish! (I

had previously blackened this wheel as an experiment - it all got turned

off during the next stages!) |

|

|

The cross slide was then wound back a bit, and similarly the compound

slide. Light cuts were then taken off the wheel tyre, but leaving about

.010" on the tyre above the desired final diameter. The flange was then

reduced to its final diameter (tyre diameter plus .036") but with square

ends. |

|

| The rounding of the flange was done with a file.

Ideally, this would be with a form tool, but I was trying this out, and it

seemed to work. I used a bastard file to get a rough shape (make sure you

have a file handle and also hold both ends of the file when doing this)

and finished off with a fine needle file, with the same safety provisos.

Finally, the tyre was reduced to the correct diameter, and once the tool

had reached the flange, it was pulled back.

|  |

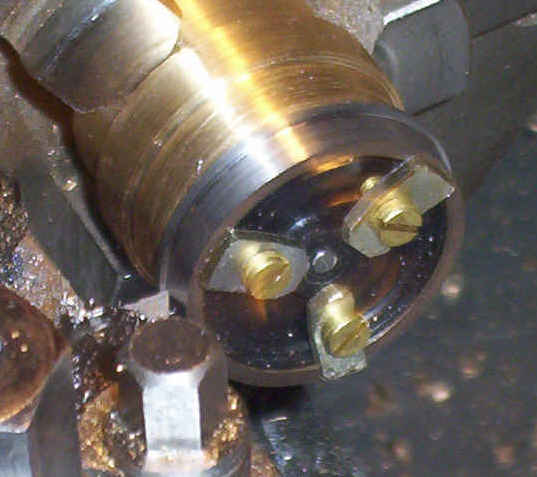

| Loosen a clamping screw, and turn the clamping strip

through 90 degrees. Tighten, and do the same for the others, one by one.

You have now mounted the wheel ready for reducing the width. In theory,

you need to take .020" off the face of the wheel, but if you do this, you

will take the front of the tyre off and reveal the plastic underneath, so

the rim could fall off. Mine didn't, but take light cuts. As a final

operation, put a 45 degree chamfer on the edge of the tyre using a file,

and polish the wheel tyre with some "Scotchbright" or similar. The wheel

is done, so move onto the next one! |

|

|

| All in all, it takes me just over half an hour to do a set

of wheels for one wagon. Is it worth it? Well, I will close with a photo

of the wheels on a nearly finished wagon, and let you be the judge. |

|

| |